-

Conducibili di supercalorificatore

-

Parete della membrana della caldaia

-

Economizzatore della caldaia

-

Metropolitana di aletta della caldaia

-

cilindro a vapore della caldaia

-

Pannello di parete dell'acqua della caldaia

-

Codici di caldaia

-

Surriscaldatore e riscaldatore

-

Caldaia Pre riscaldatore d'aria

-

Surriscaldatore della caldaia

-

AlexanderFornitori attendibili

AlexanderFornitori attendibili -

LouisE' stato un piacere lavorare con te.

LouisE' stato un piacere lavorare con te.

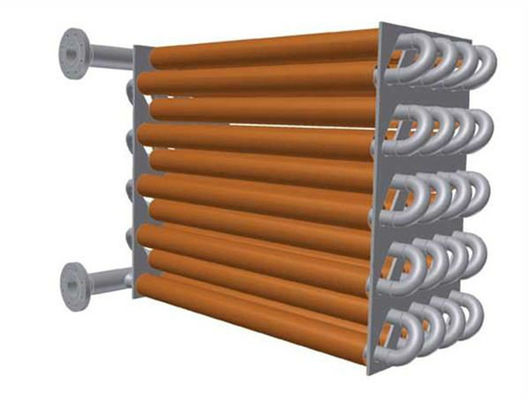

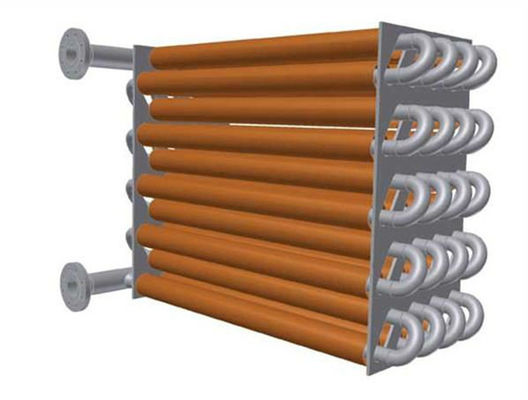

Economizzatore per caldaia ad alta efficienza con produzione di vapore max. 20 t/h per sistemi a circolazione naturale di centrali elettriche

Contattatemi per campioni e buoni.

whatsapp:0086 18588475571

WeChat: 0086 18588475571

Skype: sales10@aixton.com

Se avete qualche problema, offriamo assistenza online 24 ore su 24.

x| Tipo | Circolazione naturale | Utilizzo | Centrale elettrica |

|---|---|---|---|

| Struttura | tubo dell'acqua | Pressione | Alta pressione |

| Produzione di vapore | Max. 20 t/h | Stile | orizzontale |

| Carburante | Fabbricazione a carbone | Produzione | Acqua calda |

| Combustibile di progettazione | Combustibile a carbone | Materiale | Placca di acciaio per caldaie speciali |

| Tipo di carburante | Gas da forno al coke | Peso | 1-20 tonnellate |

| Processo di fusione | EF+LF + VD | Norma di UT | ASTM A388 o EN10228 |

| Standard di materiale | ASTM, en o iso | ||

| Evidenziare | Economizzatore per caldaia max. 20 t/h,Economisatore per caldaie a circolazione naturale,Scambiatore di calore per centrali elettriche |

||

Gli economizzatori per caldaie sono dispositivi di scambio termico con tubi a pinne che riscaldano liquidi (in genere acqua) fino al punto di ebollizione, ma non oltre il punto di ebollizione.

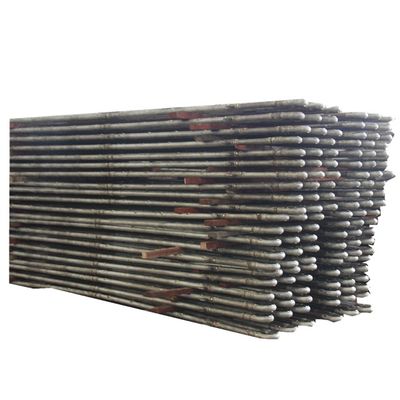

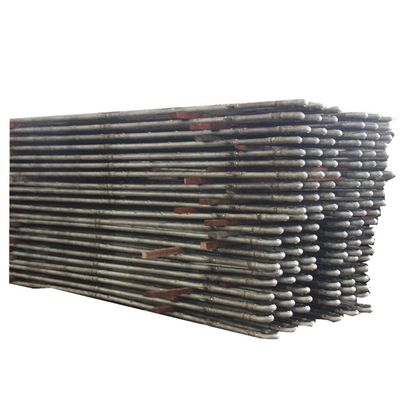

- Economisatori a tubo nudo

- Economisatori di tubi a pinne H

- Economisatori di tubi a pinne a spirale

L'economizzatore per tubi a pinne H è uno scambiatore di calore altamente efficiente costituito da tubi a pinne H. Rispetto agli economizzatori per tubi nudi, i modelli di tubi a pinne H offrono:

- Aumento della superficie di scambio termico

- Numero ridotto di tubi necessari

- Area di flusso di gas di combustione ampliata per ridurre la velocità di flusso e l'abrasione

I nostri tubi a pinne H possono essere fabbricati come doppi tubi a pinne H con elevata rigidità per applicazioni a fila lunga.L'economizer a pinne a spirale presenta un nuovo design con tubi a pinne a spirale per superare i problemi di abrasione e prolungare la vita utile.

| Descrizione | Economisatore per caldaie |

| Materiale | Acciaio legato, acciaio al carbonio, SA210C, SA213T22, ecc. |

| Norma relativa ai materiali | ASTM, EN o ISO ecc. |

| Dimensione | Personalizzato |

| Peso | 10 tonnellate - 1000 tonnellate |

| Processo di fusione | EF+LF+VD |

| Processo | Materiale→Ingot→Rolling a caldo/freddo→Trattamento termico (normalizzazione + temperatura)→Isposizione→la lavorazione grezza→UT→secondo trattamento termico→la lavorazione finale→Isposizione |

| Norma UT | ASTM A388 o EN10228, ecc. |

- Rapporto sulla prova d'urto e sul calcolo della resistenza con informazioni sui materiali applicati

- Rapporto 100% NDT (ispezione non distruttiva) di piastre, tubi ed elettrodi di acciaio

- Rapporto di ispezione a raggi X, raggi γ e per la prova del penetrante liquido (sema di saldatura) per garantire la qualità della caldaia

- Rapporto di prova idraulica per verificare la pressione di lavoro standard e la sicurezza

Indirizzo:No.1 Dongli Road, Donglai, città di Zhangjiagang, provincia del Jiangsu, Cina

Telefono:+86 (0) 512 5866 6196

Fax:+86(0) 512 5877 4453

Web:La Commissione ha adottato le misure necessarie per garantire che le misure di cui all'articolo 3, paragrafo 1, del regolamento (UE) n. 1308/2013 siano rispettate.