-

Conducibili di supercalorificatore

-

Parete della membrana della caldaia

-

Economizzatore della caldaia

-

Metropolitana di aletta della caldaia

-

cilindro a vapore della caldaia

-

Pannello di parete dell'acqua della caldaia

-

Codici di caldaia

-

Surriscaldatore e riscaldatore

-

Caldaia Pre riscaldatore d'aria

-

Surriscaldatore della caldaia

-

AlexanderFornitori attendibili

AlexanderFornitori attendibili -

LouisE' stato un piacere lavorare con te.

LouisE' stato un piacere lavorare con te.

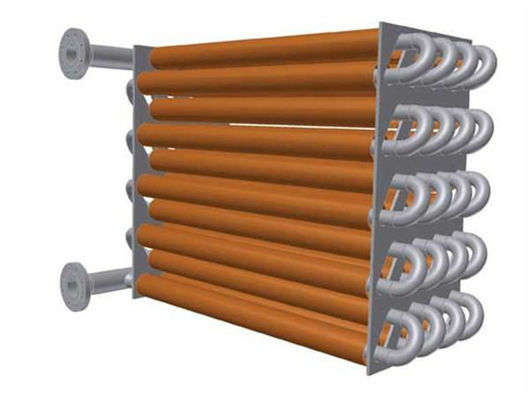

Caldaia a gas di combustione Economizer Scambiatore di calore con tubi a pinne per la produzione di vapore fino a 120 t/h e 1 anno di garanzia in circolazione naturale

Contattatemi per campioni e buoni.

whatsapp:0086 18588475571

WeChat: 0086 18588475571

Skype: sales10@aixton.com

Se avete qualche problema, offriamo assistenza online 24 ore su 24.

x| Tipo | Circolazione naturale | Struttura | tubi di fuoco e tubi d'acqua |

|---|---|---|---|

| Pressione | Basso/ad alta pressione | Produzione di vapore | Max. 120T/H. |

| Stile | Verticale | Carburante | Carbone / Gas / Calore a carbone / Calore idrico |

| Produzione | Acqua calda/vapore | Materiale | Acciaio al carbonio, acciaio inossidabile, acciaio in lega |

| Standard di materiale | ASTM, EN o ISO ecc. | Intervallo di peso | Min: 10 tonnellate max.:1000 tonnellate |

| Processo di fusione | EF+LF + VD | Processo | Materiale-> INGOT -> Rolling a freddo/a freddo-> Trattamento termico (normalizzazione+ temp |

| Norma di UT | ASTM A388 o EN10228, ecc. | Tipo di scambiatore di calore | Economizzatore per tubi con pinne H. |

| Tipo di tubo | Double H Finned Tubes | ||

| Evidenziare | Economisatore per caldaie di produzione di vapore di 120 t/h,1 anno di garanzia per lo scambiatore di calore,Economisatore di gas di scarico di circolazione naturale |

||

Gli economizzatori per caldaie sono dispositivi di scambio termico ad alta efficienza con tubi alettati progettati per riscaldare liquidi (tipicamente acqua) senza superare il punto di ebollizione del liquido. Produciamo tre tipi di economizzatori per caldaie:

- Economizzatore a tubi lisci

- Economizzatore a tubi con alette ad H

- Economizzatore a tubi con alette a spirale

L'economizzatore a tubi con alette ad H è un progetto particolarmente efficiente composto da tubi con alette ad H. Rispetto agli economizzatori a tubi lisci, i modelli a tubi con alette ad H offrono diversi vantaggi:

- Maggiore area di scambio termico

- Riduzione del numero di tubi necessari

- Area di flusso dei gas di scarico ampliata per diminuire la velocità del flusso e l'abrasione

- Disponibile nella configurazione a tubi con alette ad H doppie per una maggiore rigidità nelle file di tubi lunghi

L'economizzatore a spirale rappresenta la nostra ultima innovazione progettuale, con tubi alettati a spirale che affrontano efficacemente i problemi di abrasione e prolungano la durata.

| Descrizione | Economizzatore per caldaia |

|---|---|

| Materiale | Acciaio legato, acciaio al carbonio, SA210C, SA213T22, ecc. |

| Standard del materiale | ASTM, EN o ISO ecc. |

| Dimensione | Personalizzazione |

| Peso | Min: 10 tonnellate Max.: 1000 tonnellate |

| Processo di fusione | EF+LF + VD |

| Processo | Materiale→Lingotto → Laminazione a caldo/freddo→ Trattamento termico (Normalizzazione+ tempra) → Ispezione →lavorazione grezza→UT →2° Trattamento termico →lavorazione di finitura →Ispezione |

| Standard UT | ASTM A388 o EN10228, ecc. |

- Test di impatto e rapporto di calcolo della resistenza con informazioni sui materiali applicati

- Rapporto di ispezione 100% NDT (ispezione non distruttiva) di piastre, tubi ed elettrodi in acciaio

- Rapporto di ispezione a raggi X, raggi γ e test di penetrazione di liquidi (saldatura) per garantire la completa qualità della caldaia

- Rapporto di prova idraulica per verificare la pressione di esercizio standard e la sicurezza