Tutti i prodotti

-

Conducibili di supercalorificatore

-

Parete della membrana della caldaia

-

Economizzatore della caldaia

-

Metropolitana di aletta della caldaia

-

cilindro a vapore della caldaia

-

Pannello di parete dell'acqua della caldaia

-

Codici di caldaia

-

Surriscaldatore e riscaldatore

-

Caldaia Pre riscaldatore d'aria

-

Surriscaldatore della caldaia

-

AlexanderFornitori attendibili

AlexanderFornitori attendibili -

LouisE' stato un piacere lavorare con te.

LouisE' stato un piacere lavorare con te.

Economisatore per caldaie ad alta efficienza con produzione di vapore massima di 20 t/h e garanzia di 5 anni per uso industriale

Contattatemi per campioni e buoni.

whatsapp:0086 18588475571

WeChat: 0086 18588475571

Skype: sales10@aixton.com

Se avete qualche problema, offriamo assistenza online 24 ore su 24.

xDettagli

| Tipo | Circolazione naturale | Struttura | tubi di fuoco e tubi d'acqua |

|---|---|---|---|

| Pressione | Basso/ad alta pressione | Produzione di vapore | Max. 20 t/h |

| Stile | Verticale | Carburante | Carbone / Gas / Calore a carbone / Calore idrico |

| Produzione | Acqua calda/vapore | Trattamento superficiale | Dipinto |

| Materiale | Acciaio in lega, acciaio al carbonio, SA210C, SA213T22 | Standard di materiale | ASTM, en o iso |

| Intervallo di peso | Da 10 tonnellate a 1000 tonnellate | Processo di fusione | EF+LF + VD |

| Processo | Materiale-> INGOT-> ROLLING CALDO/COLD-> TRATTAMENTO CALORE-> ISPEZIONE-> MACCHININE | Norma di UT | ASTM A388 o EN10228 |

| Trattamento termico | Normalizzare+ temperamento | ||

| Evidenziare | Economizzatore per caldaia con produzione di vapore max. 20 t/h,5 anni di garanzia Economizer caldaia,Economisatore per caldaie per uso industriale |

||

Descrizione di prodotto

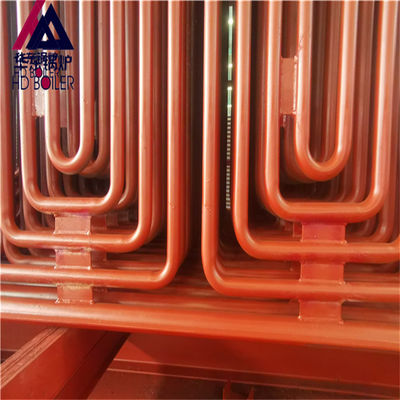

Ricambi per economizzatore per caldaia, apparecchiature per caldaie a gas di scarico, caldaia a vapore

Descrizione del prodotto

Gli economizzatori per caldaie sono dispositivi di scambio termico con tubi alettati che riscaldano i liquidi (tipicamente acqua) senza superare il punto di ebollizione del liquido. Produciamo tre tipi di economizzatori per caldaie:

- Economizzatore a tubo nudo

- Economizzatore a tubo alettato a H

- Economizzatore a tubo alettato a spirale

L'economizzatore a tubo alettato a H è uno scambiatore di calore ad alta efficienza composto da tubi alettati a H. Rispetto agli economizzatori a tubo nudo, offre:

- Area di scambio termico maggiore con meno tubi

- Maggiore area di flusso dei gas di scarico per ridurre la velocità del flusso e l'abrasione

- Disponibile come tubi alettati a doppia H per una maggiore rigidità nelle lunghe file di tubi

L'economizzatore alettato a spirale presenta apparecchiature di trasferimento del calore di nuova concezione con tubi alettati a spirale per superare la grave abrasione e prolungare la durata.

Funzione

L'economizzatore riduce i costi di raffreddamento consentendo l'arresto del compressore mantenendo al contempo un'adeguata capacità di raffreddamento, con conseguente notevole risparmio energetico.

Specifiche

| Descrizione | Economizzatore per caldaia |

|---|---|

| Materiale | Acciaio legato, acciaio al carbonio, SA210C, SA213T22, ecc. |

| Standard del materiale | ASTM, EN o ISO ecc. |

| Dimensione | Personalizzazione |

| Peso | Min: 10 tonnellate Max.:1000 tonnellate |

| Processo di fusione | EF+LF + VD |

| Processo | Materiale→Lingotto → Laminazione a caldo/freddo→ Trattamento termico (Normalizzazione+ tempra) → Ispezione →lavorazione grezza→UT →2° Trattamento termico →lavorazione di finitura →Ispezione |

| Standard UT | ASTM A388 o EN10228, ecc |

Controllo di qualità

- Test di impatto e rapporto di calcolo della resistenza con informazioni sui materiali applicati

- Rapporto di ispezione 100% NDT (ispezione non distruttiva) di piastre, tubi ed elettrodi in acciaio

- Rapporto di ispezione a raggi X, raggi γ e test di penetrazione del liquido (giunto di saldatura)

- Rapporto di prova idraulica per garantire la pressione di esercizio standard e la sicurezza

Prodotti simili

Informazioni sull'azienda

Certificato

Imballaggio e spedizione

FAQ

Contattaci

Prodotti raccomandati