-

Conducibili di supercalorificatore

-

Parete della membrana della caldaia

-

Economizzatore della caldaia

-

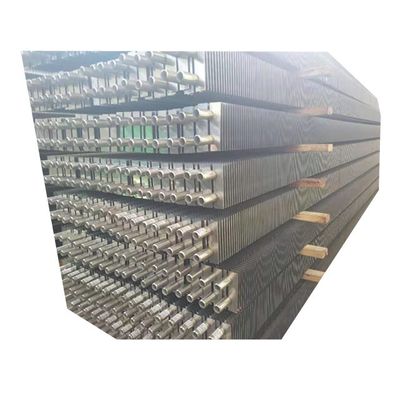

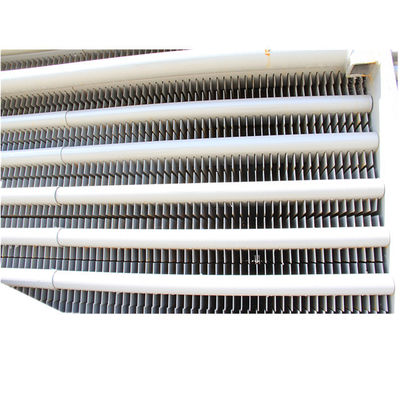

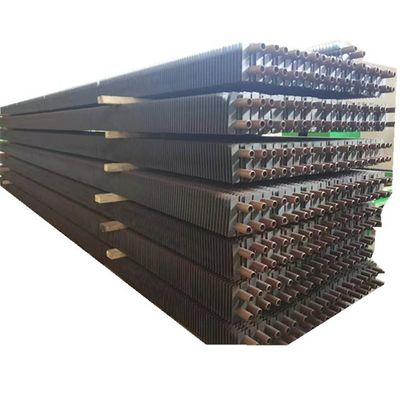

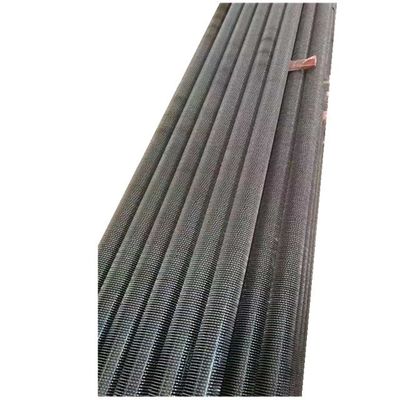

Metropolitana di aletta della caldaia

-

cilindro a vapore della caldaia

-

Pannello di parete dell'acqua della caldaia

-

Codici di caldaia

-

Surriscaldatore e riscaldatore

-

Caldaia Pre riscaldatore d'aria

-

Surriscaldatore della caldaia

-

AlexanderFornitori attendibili

AlexanderFornitori attendibili -

LouisE' stato un piacere lavorare con te.

LouisE' stato un piacere lavorare con te.

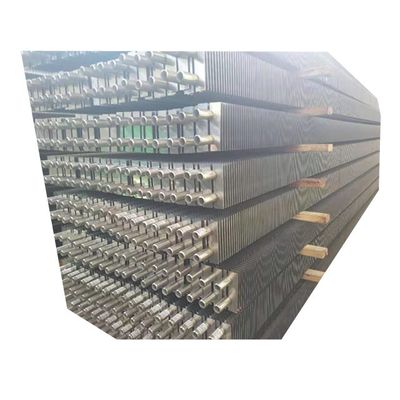

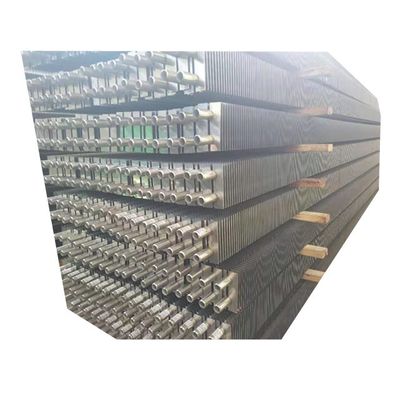

Economizzatore ad alette H con produzione di vapore max 20 t/h, 1 anno di garanzia e 5 anni di garanzia sui componenti principali

Contattatemi per campioni e buoni.

whatsapp:0086 18588475571

WeChat: 0086 18588475571

Skype: sales10@aixton.com

Se avete qualche problema, offriamo assistenza online 24 ore su 24.

x| Tipo | Circolazione naturale | Struttura | tubi di fuoco e tubi d'acqua |

|---|---|---|---|

| Pressione | Basso/ad alta pressione | Produzione di vapore | Max. 20 t/h |

| Stile | Verticale | Carburante | Carbone / Gas / Calore a carbone / Calore idrico |

| Produzione | Acqua calda/vapore | Trattamento superficiale | Dipinto |

| Materiale | Acciaio in lega, acciaio al carbonio, SA210C, SA213T22 | Standard di materiale | ASTM, en o iso |

| Intervallo di peso | 10 ton - 1000 tonnellate | Processo di fusione | EF+LF + VD |

| Processo | Materiale-> INGOT-> ROLLING CALDO/COLD-> TRATTAMENTO CALORE-> ISPEZIONE-> MACCHININE | Norma di UT | ASTM A388 o EN10228 |

| Tipo di scambiatore di calore | Economizzatore per tubi con pinne H. | ||

| Evidenziare | Economizzatore ad alette H con produzione di vapore max 20 t/h,Economizzatore ad alette H con 1 anno di garanzia,Economizzatore ad alette H con 5 anni di garanzia sui componenti principali |

||

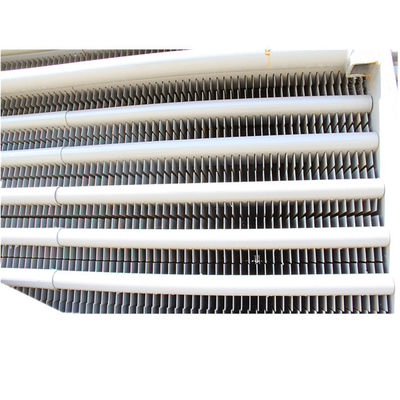

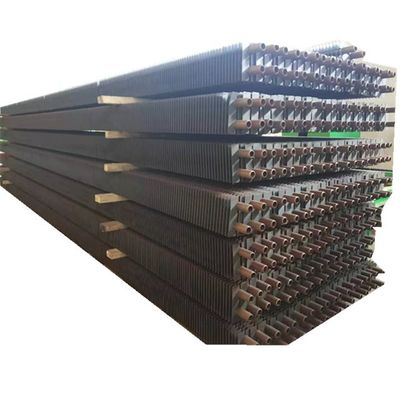

Gli economizzatori per caldaie sono dispositivi di scambio termico ad alta efficienza con tubi alettati progettati per riscaldare liquidi (tipicamente acqua) senza raggiungere il punto di ebollizione. Produciamo tre tipi di economizzatori per caldaie:

- Economizzatore a tubi lisci

- Economizzatore a tubi alettati H

- Economizzatore a tubi alettati elicoidali

- Aumenta l'area di scambio termico riducendo il numero di tubi necessari

- Aumenta l'area di flusso dei gas di scarico per ridurre la velocità del flusso e l'abrasione

- Disponibile in configurazione a doppio tubo alettato H per una maggiore rigidità nelle lunghe file di tubi

- Superiore ai progetti a tubi lisci in termini di efficienza e durata

L'economizzatore riduce significativamente i costi di raffreddamento ottimizzando l'efficienza del trasferimento di calore, consentendo l'arresto dei compressori mantenendo al contempo un'adeguata capacità di raffreddamento.

| Descrizione | Economizzatore per caldaia |

|---|---|

| Materiale | Acciaio legato, acciaio al carbonio, SA210C, SA213T22 |

| Standard del materiale | ASTM, EN o ISO |

| Dimensione | Personalizzabile |

| Peso | 10-1000 tonnellate |

| Processo di fusione | EF+LF+VD |

| Processo di fabbricazione | Materiale→Lingotto→Laminazione a caldo/freddo→Trattamento termico→Ispezione→Lavorazione grezza→UT→2° Trattamento termico→Lavorazione di finitura→Ispezione finale |

| Standard UT | ASTM A388 o EN10228 |

- Rapporti di calcolo dell'impatto e della resistenza con informazioni sui materiali

- 100% NDT (test non distruttivi) di piastre, tubi ed elettrodi in acciaio

- Ispezione a raggi X, raggi γ e test con liquidi penetranti per tutte le saldature

- Rapporti di prova idraulica per verificare la pressione di esercizio e gli standard di sicurezza